ETX - The Concept

ETX Design Guide

ETX Specifications

ETX Mechanical Specifications

Imagine all your computer and add on I/O with connectors integrated into a single PCB. Then being able to select any type, speed, or manufacturer of off-the-shelf standard CPUs to add to your personal I/O motherboard (baseboard). This is the semi-custom world of ETX (Embedded Technology eXtended). The ETX form factor of embedded computing and monitoring/control I/O should be thought of as the inverse of the traditional add on industrial I/O board concept that plugs into a CPU motherboard. ETX CPU modules are very compact (3.7" x 4.5") and mount like a daughter card with four surface mount connectors. The CPU module contains all the CPU, chipsets, memory and I/O controllers that make up a motherboard. The four interface connectors provide not only the PCI and ISA bus connections but all common (PC) peripheral functions such as graphics, USB, serial, and parallel ports, keyboard/mouse, Ethernet, and IDE. All the external motherboard connectors and your customer specific I/O functions are derived from signals that pass to the baseboard from the ETX CPU module.

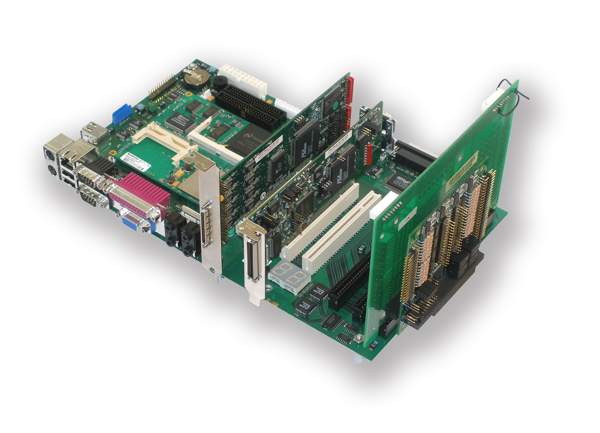

ETX-EVAL baseboard with ACCES PCI cards and PC/104 board on ISA adapter.

ETX was created to bridge the gap between custom and COTS (commercial off-the-shelf) embedded OEM solutions. Customer hardware applications and required computer peripheral I/O are combined on the same PCB baseboard or carrier. The ever changing CPU market can be made more economical by using mass produced ETX CPU modules implemented into multiple customers I/O PCB baseboards. The customer can then focus on his application rather than whether the next motherboard will work with his I/O. With I/O connections constant, system packaging simplified, and cabling eliminated, the system-level cost is greatly reduced. A diverse multi-vendor market of standardized ETX CPU modules reduces obsolescence and allows easy upgrade of processing capability. The market for COTS type boards is usually up to 1000 pieces a year while pure custom only proves to be cost effective in applications using 10,000 units a year or more. The semi-custom ETX market where the baseboard is customized and the ETX CPU is COTS excels between the world of Custom and COTS.

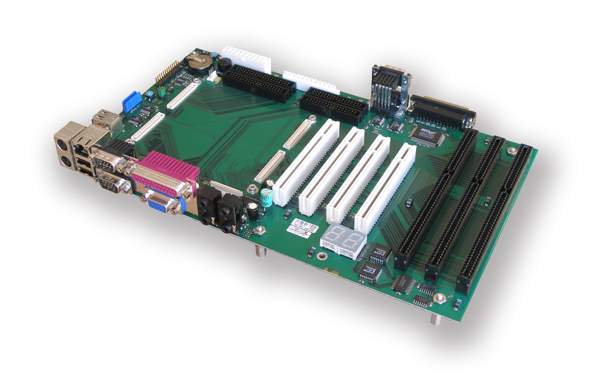

ETX-EVAL baseboard. Just add ETX CPU and I/O boards needed for your application.

ACCES I/O PRODUCTS, Inc. is the first major U.S. I/O company to introduce the semi-custom ETX baseboard concept to minimize the cost of ETX baseboards closer to the COTS market. Our hardware and software engineers can design your next ETX Baseboard solution using our large lines of analog, digital, and serial I/O as the foundation to build semi-custom baseboards. An ETX evaluation baseboard can be purchased that brings out all the computer connectors as well as PCI and ISA slots just like a regular motherboard. Any ETX CPU module can be added to the ETX evaluation board to test the optimum computer power. Then select any ACCES board required to meet your specific application. The advantage of incorporating ACCES designs and software drivers into your ETX baseboard is the reduction in NRE costs for both design and software. Using components that we already use on our I/O boards allows us greater buying power, superior delivery, and reduced inventory costs for your ETX Baseboard. The finished design cycle is greatly shortened by using the same I/O designs and ETX CPU module at the prototype stage and production phase. This new business model allows us to reduce both the cost and time thresholds for using ETX as your embedded solution.

Here are the following general steps needed to implement ETX baseboards.

1. Contact ACCES and talk to an ETX Sales Application Engineer about your OEM application including what type of I/O, processor, enclosure, and I/O location of connections are needed and what if any NRE is required.

2. Select any combination of PCI, ISA or PC/104 boards from our extensive COTS selection that meet the requirements of your OEM application.

3. Purchase an ETX evaluation baseboard, ETX CPU module and the selected I/O boards.

4. Test to confirm that hardware and software works in the application.

5. Order prototype baseboard units based on specific I/O needs, baseboard dimensions and connector locations. Different functional portions of existing plug-in ACCES boards can be implemented on the baseboard.

6. Continue development of your software application while baseboard is being designed and built. Software drivers of your baseboard will be the same as the drivers used on the I/O boards you already have with your ETX evaluation baseboard.

7. Your software and application will usually work the first time with delivery of your first prototype ETX baseboard. Customer orders production units after final verification and approval.

The ETX form factor has proven itself in many hundreds of OEM applications where product volume was insufficient to go fully custom. Total ETX CPU module sales have exceeded all other small form factor CPU boards including the popular PC/104. By using ACCES for your ETX baseboard source, your cost for entering the world of ETX has now been reduced.